SharpGradeX

SharpGradeX Excavator Series

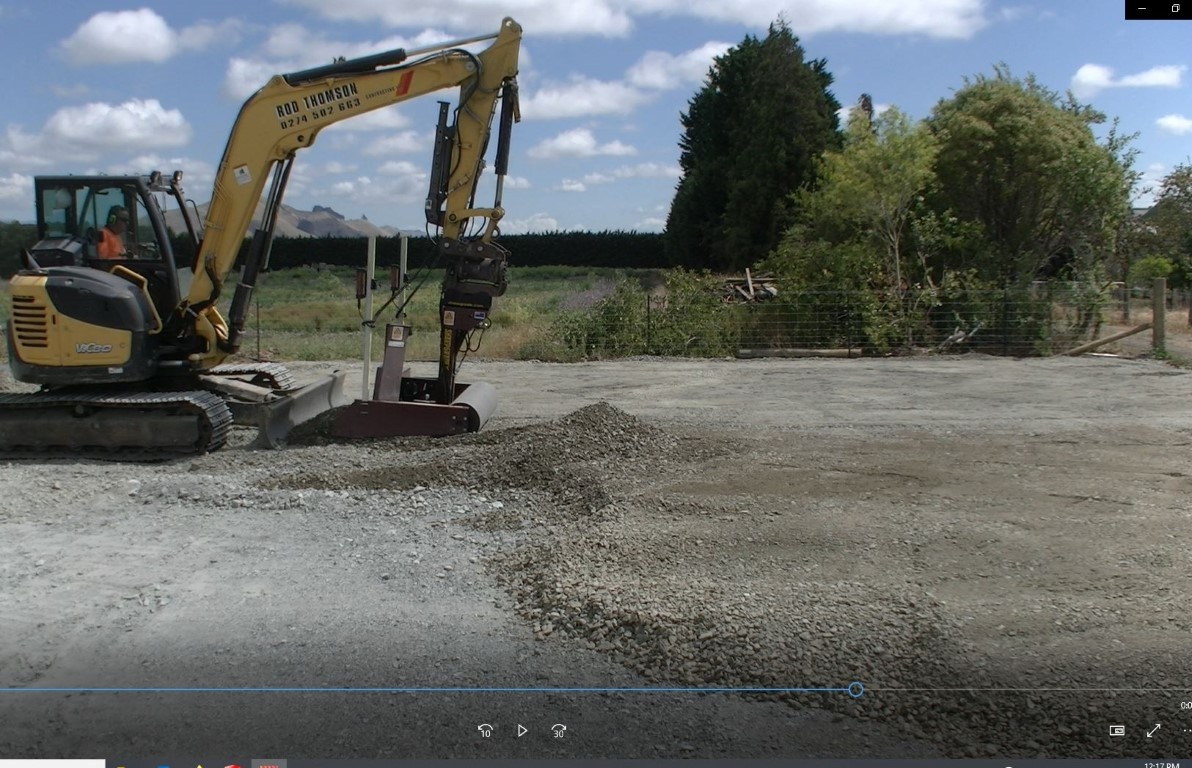

Fully automated Excavator Grading Box for 2.5 to 14 ton (5,500 to 30,000 LB), turns your excavator into a precision grading machine to grade within +/-6mm (1/4”). Uses standard 2D or 3D control system, can be used with 2D laser or 3D Total Station. Works with a Sonic to read a string line or grade match a surface. Ideal for areas where GPS will not function: indoors, beside buildings, trees etc. for curb and gutter prep, sidewalks, cycle paths, flat work, patios, drive ways etc.

- Fully automated on most excavators: operator controls stick only when in auto mode

- Quickest, most accurate design on the market: no slope sensors with latency & inaccuracy

- Accuracy +/-6mm (1/4”): Ideal for flat work, asphalt, paving etc.

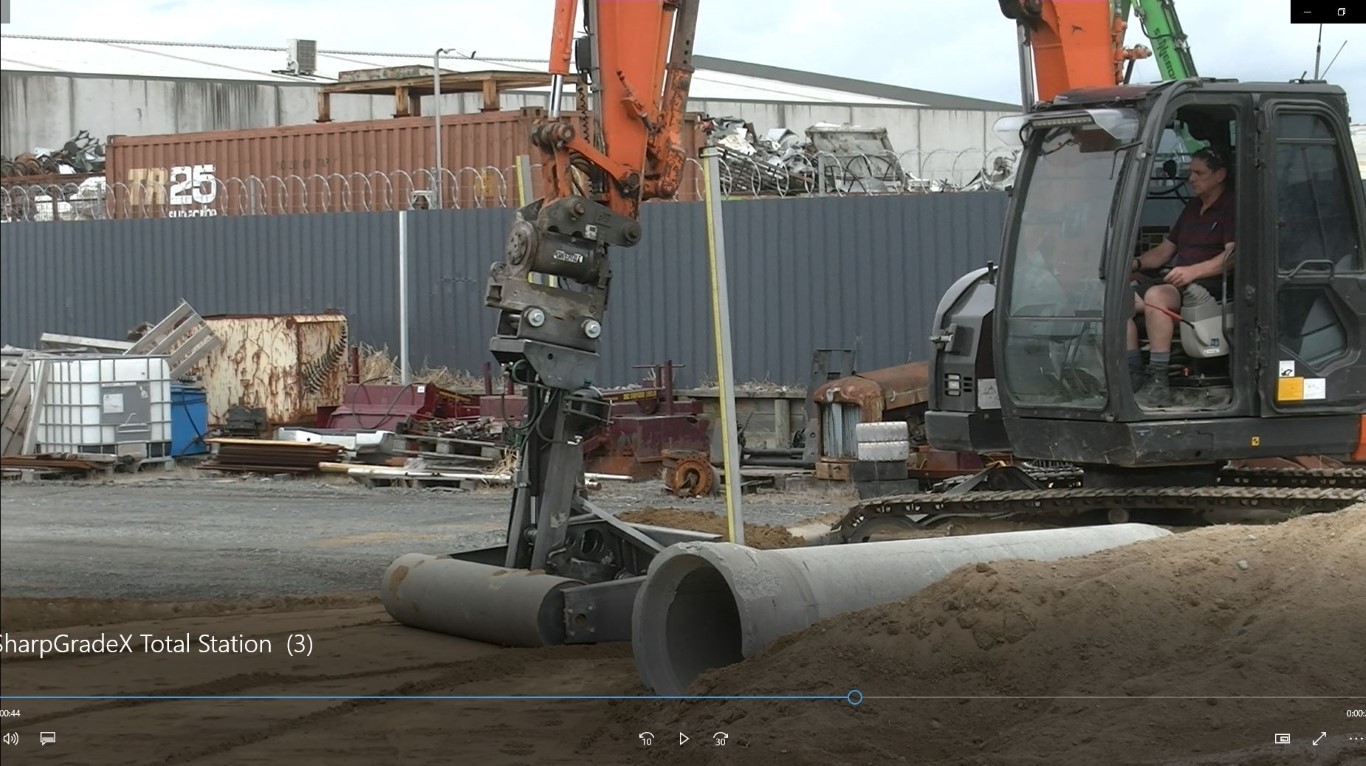

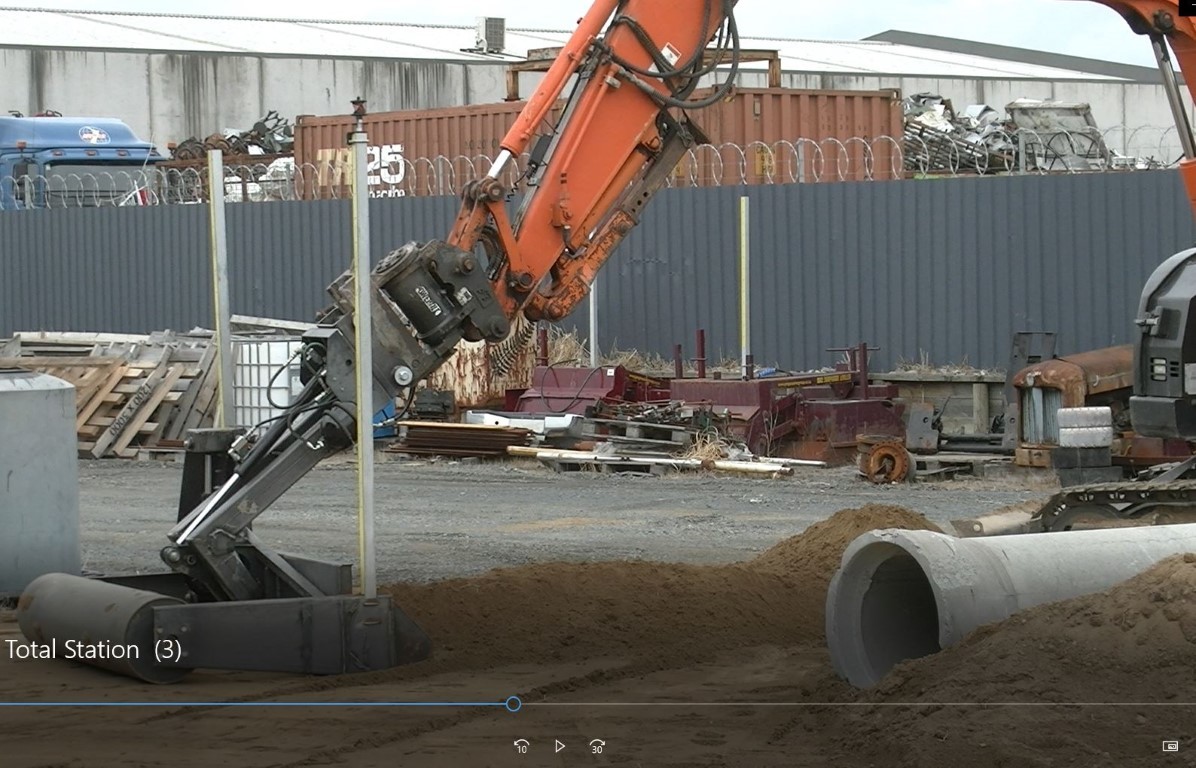

- Operates with Direct Total Station: Operates continuously, does not need to reset

- Can be used as conventional bucket: shift material to and from grading area

INTRODUCING THE WORLD’S FIRST AUTOMATED GRADING ATTACHMENT FOR EXCAVATORS

Heavy Duty series 2.4m (94”) suitable for 12 – 14 ton (26,000 – 30,000LB) excavator

Medium series 1.8m (72”) suitable for 7 – 10 ton (15,0000 – 22,000LB) excavator

Compact series 1.6m (62”) suitable for 5 – 6 ton (11,000 – 13,000LB) excavator

Junior Series series 1.2m (48”) suitable for 2.5 – 4 ton (5,500 – 9,000LB) excavator

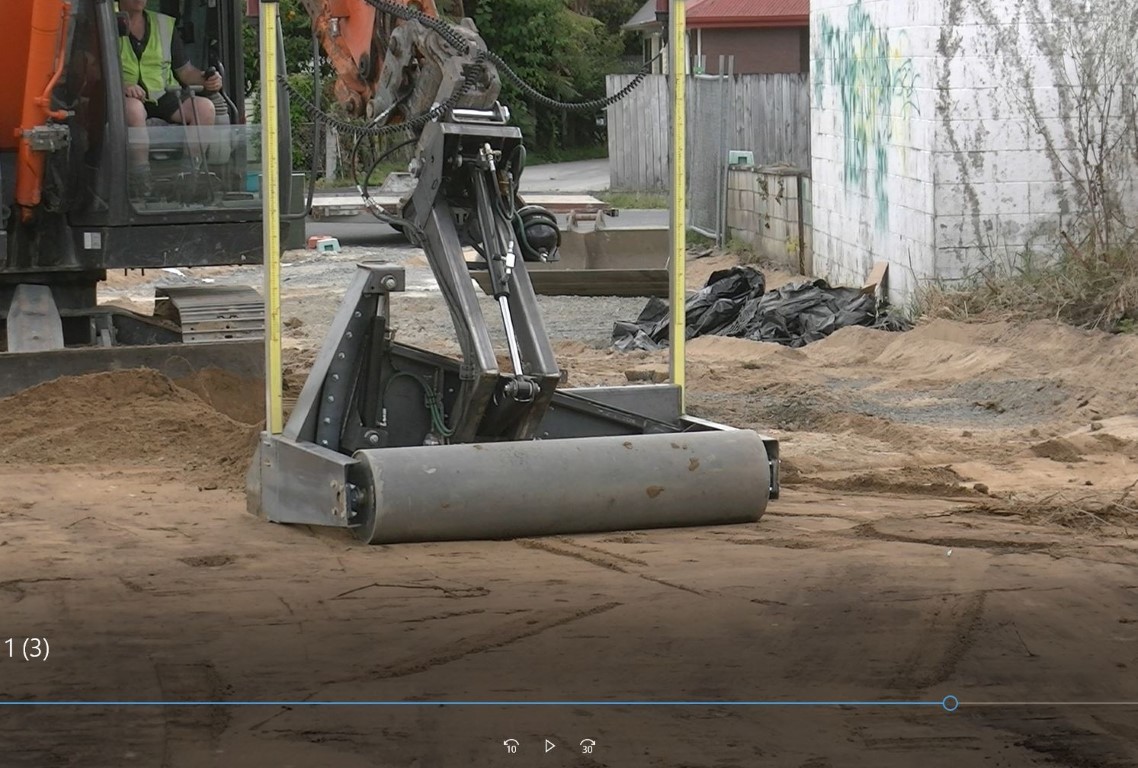

The SharpGradeX is the world’s first fully automated grading attachment for excavators. Connecting on to the conventional bucket pins, the SharpGradeX turns your excavator into a precision grading machine. All the operator has to do is position the SharpGradeX and draw the stick in towards the cab. The SharpGradeX seamlessly controls the elevation and cross fall to within +/-6mm (1/4”), with no input from the operator of the boom or bucket functions.

It is directly controlled, so does not require traditional complex excavator control systems involving GPS & multiple slope sensors with their inherent response latency. This allows us to grade up to 3 times accurately & faster, both indoors and out.

It can be fitted to virtually any brand excavator and can be swapped between base machines. It is currently available to suit base machines from 2.5 ton to 14 ton (5,500 – 30,000LB)

The SharpGradeX is available with 2D laser control, Sonic tracker and Slope sensor.

It is the first excavator grading attachment that can be directly controlled by a Total Station. As the prism is on the attachment, it is unaffected by the machine slewing and does not require to be reset every time the excavator is repositioned. The SharpGradeX is the most advanced, accurate, affordable, flexible, precision excavator grading attachment on the market.

Tasks performed by the SharpGradeX include:

- Finish grading of concrete flat work, particularly around services

- Asphalt preparation

- Catch pit preparation

- Driveway preparation

- Walking track /cycle way preparation

- Curb preparation

- Side walk preparation

Unique features

- Patent pending design: most accurate excavator grading attachment on the market

- HardiLube bushes throughout: never require greasing

- +/- 7 degrees Cross fall: sufficient to grade catch pits etc.

- Zero cross coupling: up to 3 times faster to grade than conventional designs

- Lockable grade angle position: use as a conventional bucket

- Full manual over ride using conventional excavator functions

- Grading within +/-6mm (1/4”): up to 3 times more accurate than the latest technology

- 2D and 3D compatible with Laser, Sonic, GPS & Total Station: multiple technologies

- Direct Total Station compatible: no resetting required: a world first

Questions? Have a project to discuss?

Get in touch today for a no-obligation quote.